The air compressor is one of the most important and most overlooked tools in your shop. In order to keep the compressor in great shape, you need to perform regular maintenance. What maintenance you ask? How about:

- Draining the water daily.

- Inspecting the air filter weekly.

- Checking the oil level weekly.

- Changing the oil at least once a year.

- Inspecting the belts monthly.

Drain the Water Daily

You may not know this, but an air compressor condensates as it is being used and that water collects in the air tank. Most air tanks will have a drain valve at the lowest point. You should drain the water out of the tank before or after each use. I generally drain it before I use the compressor so that I know I’m starting fresh. If your compressor has a drain plug, but no easy way to drain the water, you should install a drain valve. This can be done easily by letting all of the air out of the tank and threading in an elbow and attaching a ball valve to it.

Inspect the Air Filter Element Weekly

Inspecting the air filter element at regular intervals is essential, especially if your compressor is housed in the same area where you are doing body work or any type of sanding and painting. The filters for my Quincy compressor are rather pricey so I generally just blow the dirt out of the filter and reinstall it. To inspect the filter:

- Locate the filter housing.

- Remove the filter housing.

- Remove the filter and inspect.

- If it’s dirty, first try using air to clean it.

- If it doesn’t come clean, install a new filter.

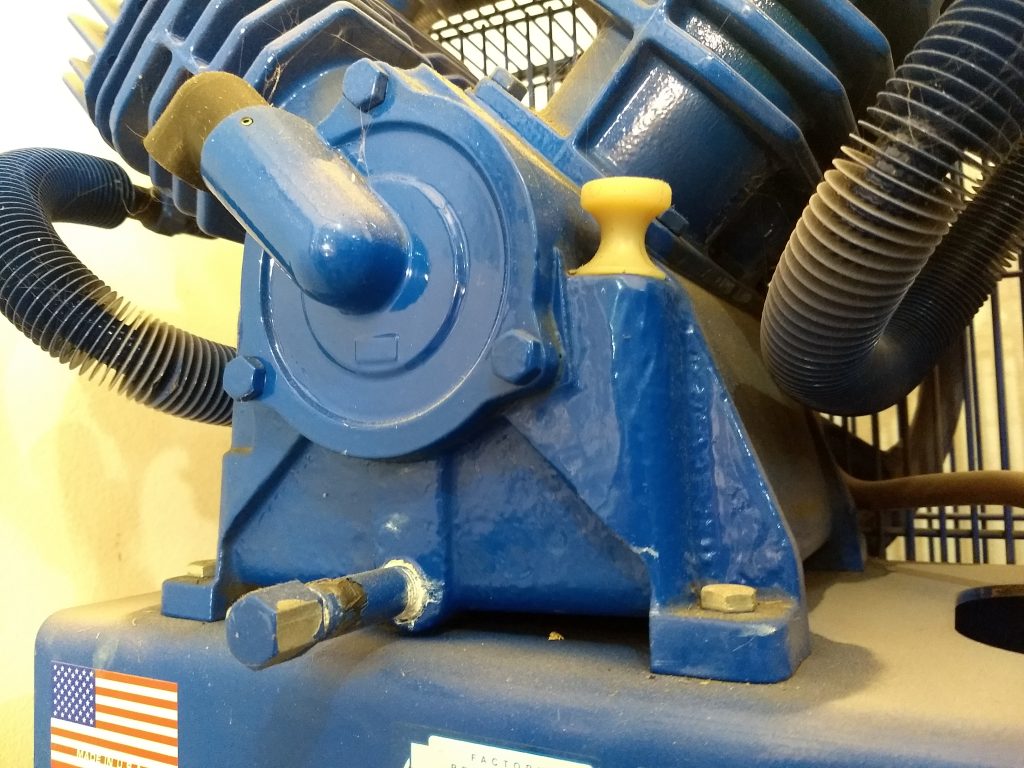

Check the Oil Level Weekly

One thing is for certain, your compressor will not run long without oil. It’s important to verify that your compressor has oil. The oil should be halfway up the sight glass or to the mark on the dip stick. If it’s low, top it off with a high quality air compressor oil like Royal Purple’s Synthetic Air Compressor Lubricant. To check the oil level:

- If your model has a dipstick, remove the dipstick and read the markings on the dipstick.

- If your model has a sight glass, verify that you have oil up to the middle of the sight glass.

Change the Oil Yearly

The oil should be changed at a minimum once a year, more often if you use your compressor daily. I like to splurge a little and get a high quality oil like Royal Purple’s Synthetic Air Compressor Lubricant. I certainly do not want anything happening to my compressor. To change the oil:

- Grab a container and a wrench.

- Locate the drain plug and while holding the container under the drain plug, remove the plug.

- Let the oil drain. This can take a while on some models. You may want to use a container that is clean and has measurements on it so you know how much oil to put back in.

- Install the drain plug. If your plug was leaking, I recommend adding some some high quality pipe thread sealant to the threads.

- Place a funnel into the fill hole and begin adding oil.

- Periodically check the oil level. Do not overfill.

Inspect the Belts Monthly

Visually inspect the belts for wear and tear and measure how much play the belt has. Your air compressor should have come with an owner’s manual and in that manual will be the specifications that define the amount of play that is considered to be normal. To inspect the belt tension:

- Disconnect the power to the air compressor.

- Remove the belt guard if equipped.

- Grab a tape measure and get the measurements from your owner’s manual.

- Press on the belt to measure the distance.

- Adjust the belt as necessary using the instructions in your owner’s manual.

Other Maintenance

In addition to the maintenance items listed above, you’ll also want to check for leaks, vibrations, and cracks. Also check that the safety/check valve is functioning properly.

Add comment