Those of you that have installed replacement quarter panels on a second generation Camaro will know about the quarter panel flange that goes between the inner structure and the rocker panel. It’s somewhat puzzling as to how all of that was spot welded from the factory because there is no access to that area. One option is to cut the flange off and weld the quarter panel to the rocker panel and that’s what I am going to show you today. This post also doubles as a how-to for smoothing the seam.

There are two alternative options near the bottom of this post that would allow you to keep the original seam.

Preparation

You’ll want to cut the flange off prior to installing the quarter panel. Don’t forget to plug weld the inner structure to the rocker panel if you had it disassembled.

Begin prepping the area by removing the paint/rust from the quarter panel and the rocker panel so that you have clean metal to work with. I use a combination of a wire wheel and black hawk strip discs to do this.

Welding

Next I tack weld the quarter panel to the rocker panel about every inch or so. Spend as much time as you need here to get the quarter panel nice and flush with the rocker panel. You can use a flat head screw driver to pry the quarter panel outwards. Generally you can use your hand to push the quarter panel inwards.

Tip: Start your weld bead on the rocker panel and carry it across to the quarter panel to avoid burn through. The bend in the rocker panel gives it more thickness.

Safety: The original rocker panels are made from galvanized sheet metal. Welding galvanized steel creates zinc oxide fumes which can cause galvanize poisoning. Ensure you have proper ventilation and that you are wearing a respirator.

Next I weld each seam solid by adding tack welds to the existing tacks until I have filled the entire seam. Using tack welds helps to keep distortion to a minimum by keeping the area cool. After each pass of adding tacks, I hit the area with compressed air to cool it down.

I then grind the welds down smooth using a combination of the cut off wheel, a 36 grit roloc disc, and a 120 grit flap disc on the grinder. Generally I’d just hit the area with 40 grit flap discs on a 4.5 inch angle grinder, but I was out of them. I’m a huge fan of the Benchmark Abrasives flap discs and cut-off wheels. They are long lasting and affordable.

Rust Prevention

Last I hit the welds with a thin coat of fiberglass filler to fill any remaining pin holes. Once the filler was dry I sanded it down and threw on a coat of rattle can paint to prevent rust until I am ready to tackle the entire shell. I also plan on going in through the jamb vent and applying some kind of paint or rust encapsulator to the weld.

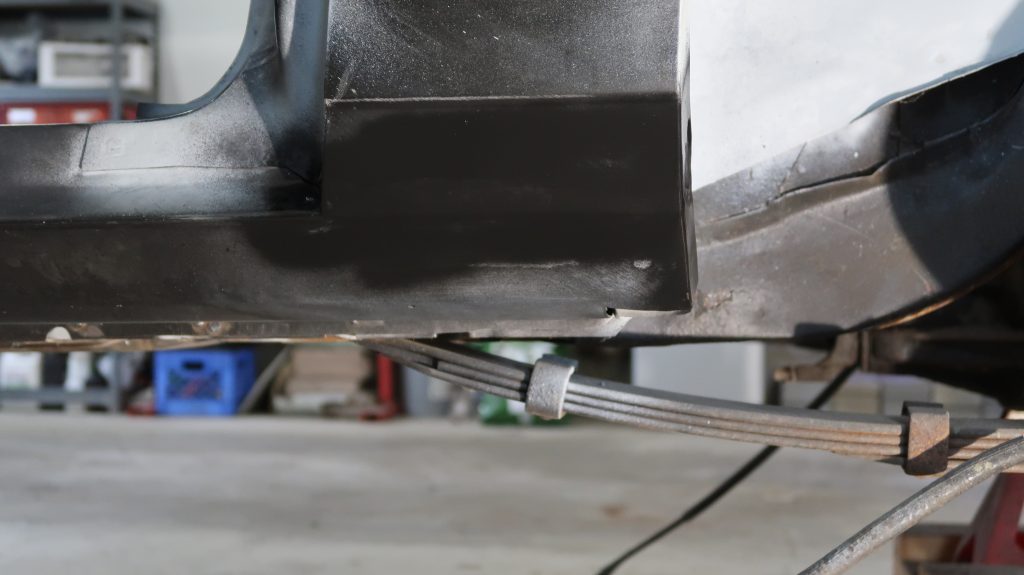

Passenger’s side quarter panel tack welded to rocker panel.

Driver’s side quarter panel tack welded to rocker panel.

Welding driver’s side quarter wheel well to rocker.

Welding passenger’s side quarter wheel well to rocker.

Fitting patch to passenger’s side quarter wheel well to rocker.

Welds ground smooth

Passenger’s side seam smoothed and painted.

Driver’s side seam smoothed and painted.

Hobart 187 Welder Settings

Alternative Options to Removing the Flange

Russ, from Double R Restorations, is going for an original restoration and plans on keeping the seams for his second generation Camaros. He is considering cutting an access panel from the inside of the car to get access to that area. This is a great option because you avoid cutting your quarter panels, you keep your welds on the inside of the car, and you keep the quarter panel flange in the original location.

Bart, from Busted Classic Garage, suggested cutting the area with the flange in a way that gives you access to weld it back to the quarter panel after you install it between the inner structure and the rocker panel. This will allow you to fit the quarter panel, then take the quarter panel off, leaving the flange area, so that you can plug weld the flange area to it’s original location between the inner structure and the quarter panel. Once plug welded, you would install the quarter panel and weld the flange area to the quarter panel.

Which option should you choose? It’s personal preference, but here are a few things to consider. If I were installing NOS quarter panels I’d be inclined to choose the option of cutting an access panel. I think I’d have a hard time cutting up NOS quarter panels. If installing reproduction quarter panels I’d likely take the approach of cutting the flange in a way that would allow me to install it between the inner structure and rocker panel, but also weld it to the quarter panel. Both options allow you to keep the original seam.

Add comment